MCCB (Moulded Case Circuit Breaker) is an Electrical protective device, which is used to protect the electrical installation against overload and short circuit faults that arise because of excessive current. Wide current ratings and high breaking capacities, Manual remote operation, the ability to change the settings according to the applications are some of the key features of the device.

Tmax XT MCCBs guarantee a very high level of performance while being progressively smaller and this range gives better performance, higher protection, and greater precise metering than equivalent devices, and can manage from 16A up to 1600A loads. Some devices of Tmax XT MCCB family’s integrated connectivity links electronic communication devices such as smartphones, tablets, and PCs to data analysis tools on the ABB AbilityTM cloud platform in real-time. These are the first moulded case circuit-breakers to become an active element inside the electrical plant without using external accessories. They can access, monitor, & control information remotely, anywhere at any time & Improving efficiency and saving energy

Tmax XT MCCBs and their accessories comply with IEC 60947-2, EN 60947 international Standards.

Product Scope:

MCCB should be accessible in fixed or plug-in/withdrawable forms as well as in 3-pole and 4-pole forms. There are 8 models (XT1, XT2, XT3, XT4, XT5, XT6, XT7 & XT7M) and they can handle load current from 16A up to 1600A. Some devices in this series can work on both AC and DC supplies. The rated service voltage of 690V (AC 50/60 Hz) is applicable for all the devices and 500V DC and 750V DC are applicable for XT1-XT6 in thermal magnetic trip units respectively. The breaking capacities of this series range from 18 kA to 200 kA at 415VAC.

Trip Units:

Thermal-magnetic trip unit:

The thermal-magnetic trip units are used for the protection of AC and DC systems. They are a solution for systems where only protection against overloads and short-circuits are needed. There are four types of thermal-magnetic trip units available for different applications.

|

Application

|

Trip Unit

|

L - Overload Protection

|

I - Short-circuit Protection

|

|

Current Threshold

|

Trip Time

|

Current Threshold

|

Trip Time

|

|

Power Distribution

Protection

|

TMD

|

Adjustable

|

Fixed

|

Fixed

|

Fixed instantaneous

|

|

TMA

|

Adjustable

|

Fixed

|

Adjustable

|

Fixed instantaneous

|

|

Motor Protection

|

MA

|

-

|

-

|

Adjustable

|

Fixed instantaneous

|

|

Generator Protection

|

TMG

|

Adjustable

|

Fixed

|

Adjustable

|

Fixed instantaneous

|

*Key:

- Current threshold for short-circuit protection

- Rotary switch for short-circuit protection

- Current threshold for overload protection

- Rotary switch for overload threshold setting

Ekip Dip Electronic Trip Unit:

The Ekip Dip is the initial level of electronic trip unit, used for the protection of AC systems. There are such a lot of special characteristics included in this unit than thermal-magnetic trip unit. The unit has dip switches for each overload and short circuit protection, and they provide manual settings when the trip unit is off and there is a LED indication on the front, it shows the status of the discharge (on/off) and provides information about the protection tripped when the Ekip T&P accessory is connected. This unit allows a connection to a laptop with the Ekip Connect program. Thermal memory is a unique function, and it records the trips which have occurred in the last few minutes. External sensor for the neutral phase might be included for the 3-pole version with earth fault protection (G). In this manner, the external neutral phase is protected and uninterrupted. Communication with Modbus RTU is possible for XT2, XT4-XT5, XT7, if units are equipped with Ekip LS/I, LSI or Ekip LSIG trip units.

|

Application

|

Trip Unit

|

L-Overload Protection

|

S-Selective Short Circuit Protection

|

I-Short Circuit Protection

|

|

Current Threshold

|

Trip Time

|

Current Threshold

|

Trip Time

|

Current Threshold

|

Trip Time

|

|

Power Distribution Protection

|

Ekip Dip

|

LS/I

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Fixed

|

|

LIG

|

Adjustable

|

Adjustable

|

-

|

-

|

Adjustable

|

Fixed

|

|

LSI

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Fixed

|

|

LSIG

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Fixed

|

|

Motor Protection

|

Ekip M Dip

|

I

|

-

|

-

|

-

|

-

|

Adjustable

|

Fixed

|

|

LIU

|

Adjustable

|

Adjustable

|

-

|

-

|

Adjustable

|

Fixed

|

|

Generator Protection

|

Ekip G Dip

|

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Adjustable

|

Fixed

|

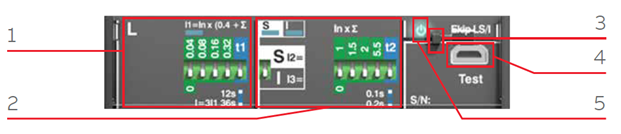

*Key:

- Dip switches for an overload protection setting

- Dip switches for short-circuit and time delayed short-circuit protection settings.

- Slot for lead seal

- Test connector

- Power-on LED.

Ekip Touch/Hi-Touch:

This is a highly developed trip unit that goes beyond all limits. This device has so many unique advantages that require for industries which include all the features of the two trip units described earlier plus more. The Ekip Touch/Hi-Touch trip units can be integrated perfectly into all automation, energy management systems to improve productivity, energy consumption and remote control. As before, these trip units can be divided into multiple categories according to the applications. Ekip Touch LSI, Ekip Touch LSIG, Ekip Touch Measuring LSI and Ekip Touch Measuring LSIG can be used for the protection of power distributions. Ekip M Touch LRIU is available for motor protection and Ekip G Touch LSIG & Ekip G Hi-Touch LSIG trip units can be used for generator protection. Interaction of trip unit can be done by several ways, such as front LCD display, Smartphone via Bluetooth (it is possible to set and check all the measurements and information directly from a smartphone thanks to EPiC app) and PC with Ekip Connect (by using the Ekip T&P cable, the trip unit can be easily connected to a USB port and using the Ekip Connect program, it is possible to fully interact with the trip unit). With these features, commissioning practices can be easily conducted by minimizing errors because the setting, testing, and downloading of reports can be carried out directly from a smartphone, tablet, or PC. The circuit-breakers can be equipped with communication modules for Modbus, Profibus, and DeviceNet™ protocols as well as Modbus TCP, Profinet, EtherNet/IP™ and IEC61850. Protection functions can be easily set and adding other functional packages (Voltage protection, Frequency protection, power protection, ROCOF protection, Adaptive protection, etc.) in the future is always possible.

*Key:

- Power-on LED; pre alarm LED; alarm LED

- Test and programming connector

- Display

- Home push-button to return to homepage

- Push-button for testing and tripping information

Construction characteristics:

The safety of the operator is a very important factor in the use of electric devices. Therefore, more attention should be given to electrical insulation. The Tmax XT circuit-breaker has double insulation between the live power parts (excluding the terminals), the front parts of the apparatus and accessories are completely segregated from the power circuit, preventing any risk of contact with live parts. This characteristic provides greater protection for the device operator and other devices as well.